GEORGE technical training: Learn more about ocean observing platforms

Curious to learn more about the technology and operations of ocean observing platforms? GEORGE project is here to answer your needs.

From the 21st to the 25th of May 2024, scientists and technicians from EMSO, Euro-Argo and ICOS ERIC communities met in Villefranche-sur-Mer to be trained on observing platforms, these oceanographic instruments used by scientists to take the pulse of the ocean.

The training was organised by the Laboratoire d’Océanographie de Villefranche (LOV) and featured several commonly used platforms in Ocean Research Infrastructures, such as: EGIM, Argo profiling floats, Sailbuoys and gliders.

One day was dedicated to the Argo profiling floats and aimed at explaining to experienced or new users the main steps from the reception of the float to its deployment and monitoring. Romain Cancouët and Estérine Evrard, from the Euro-Argo ERIC Office, together with Edouard Leymarie and Antoine Poteau from LOV, proposed a full day of tips and tricks on Argo floats, with some additional demonstrations of Argo web interface features

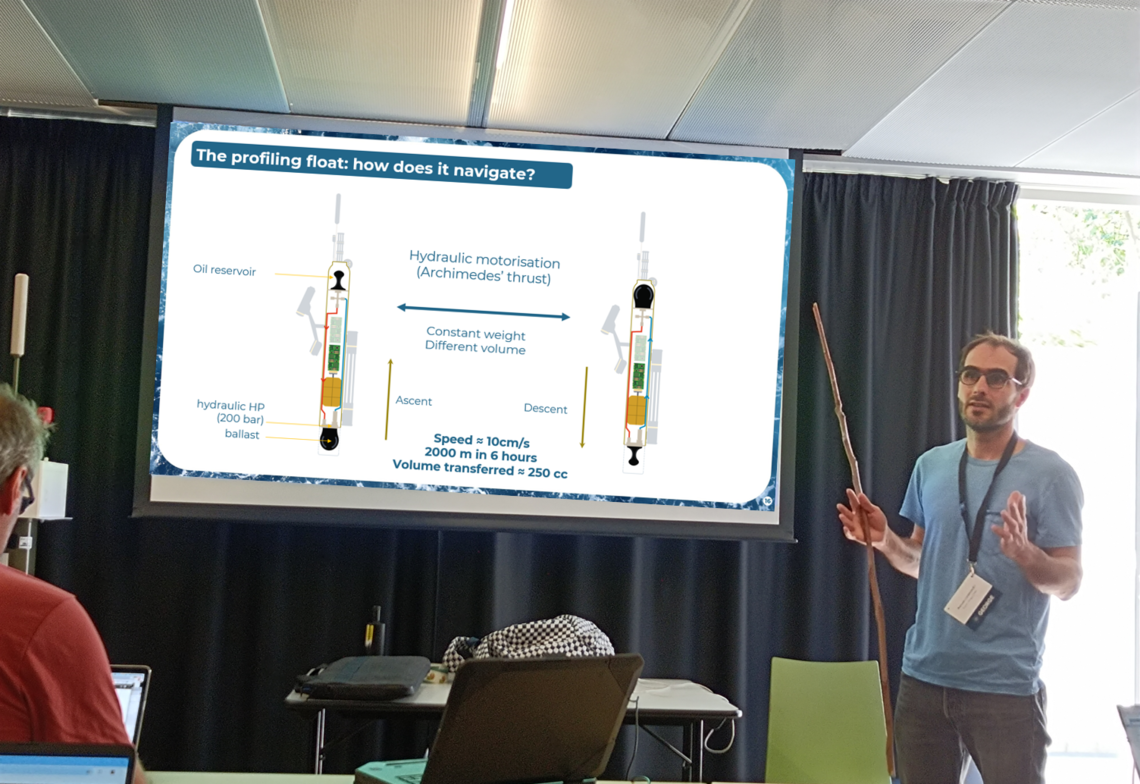

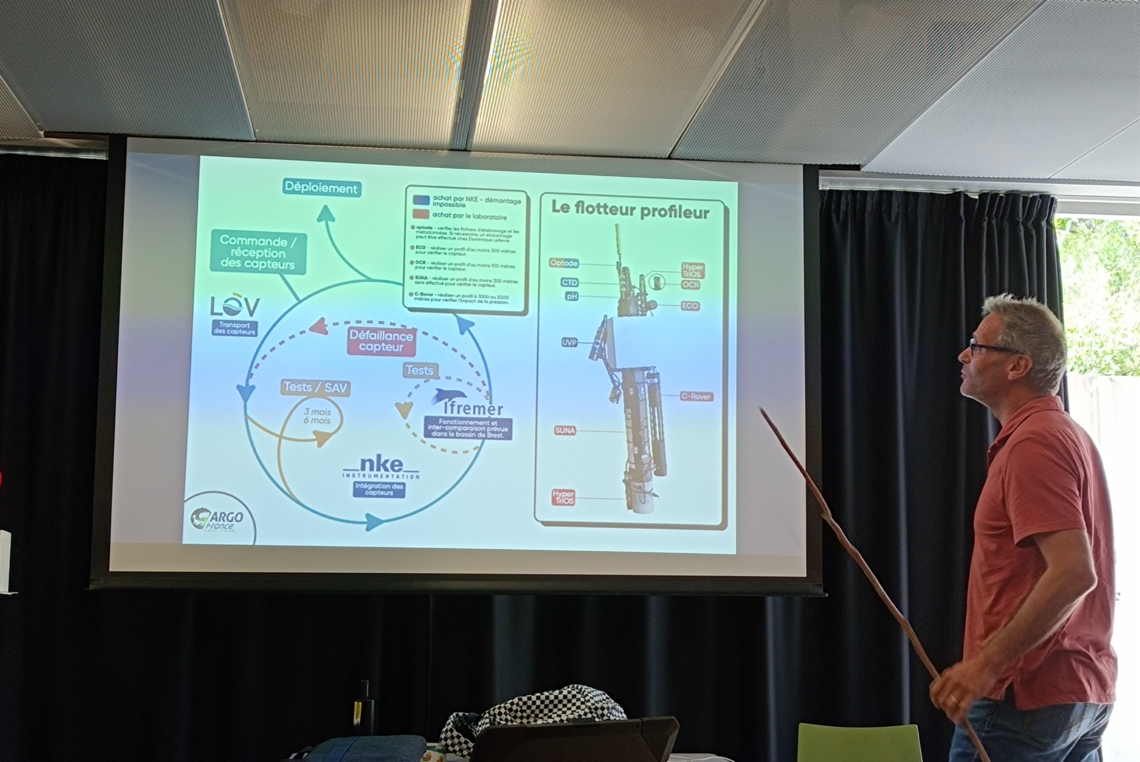

Two profiling float models were presented: the Arvor float, measuring the temperature, salinity and even dissolved oxygen of the water column, and the Provor CTS5 float, measuring an additional set of BGC parameters. These models, built by nke manufacturer, are the most used by the Euro-Argo community.

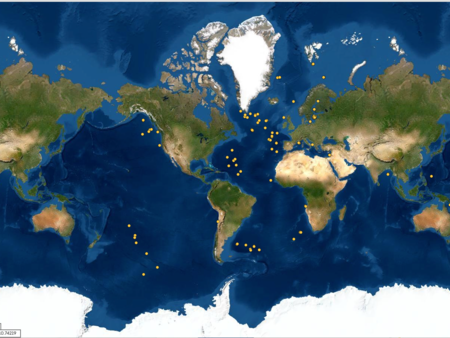

The day started with a presentation of the Argo international programme, the research infrastructure and the data management system, to get an overview of its organisation. Then, the trainees discovered the different types of profilers and basic technical principles, as well as some operational points such as logistics, customs … (photos 1 & 2)

Photo 1: Basic principles of an Argo float explained by Romain Cancouët, operational engineer at Euro-Argo ERIC (c) Euro-Argo ERIC | Photo 2: Operational steps before deployment presented by Antoine Poteau, engineer at LOV (c) Euro-Argo ERIC |

Special features of the CTS5 were also addressed: the graphic user interface (GUI) for pre-programming, iridium server and data decoding were part of the presentation on the Provor CTS5 float (photo 3).

The last part of the day focused on a hands-on activity on the floats (photo 4) and showcased existing online tools. The Euro-Argo fleetmonitoring dashboard used to monitor the floats at sea, the recovery website and some recovery examples, such as the recent NAARCO campaign, as well as the graphic interface to visualise BGC data were explained through a short demo.

Photo 3: Iridium transmission and Rudics server for Provor CTS5 showcased by Edouard Leymarie, engineer at LOV (c) Euro-Argo ERIC | Photo 4: Hands-on activity on an Arvor float explained by Estérine Evrard (c) ICOS ERIC |

This first training allowed participants to learn about the capabilities of the different platforms and how to use them, with the new sensors that will be integrated thanks to the GEORGE project.

Stay tuned, an online component of the training course is in preparation! You will be able to find learning material on this platform and test your new knowledge.